Biking to work in the frigid cold and looking sharp all day long is getting easier for guys in Chicago and beyond thanks to a local sustainable-clothing designer.

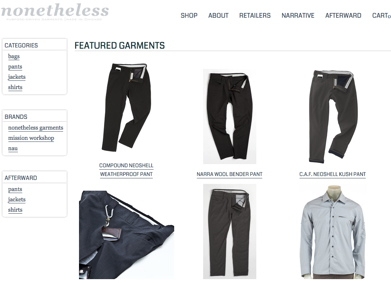

Jonathan Shaun, an urban cyclist who has designed snowboard wear and worked for sustainable consulting and clothing companies, has launched a new Chicago company called Nonetheless Garments. He’s designed a line of weather-proof pants (and some jackets, too) that can take diehard year-round cyclists through the slushy streets of Chicago to a polished look at the office and then out to dinner or a night on the town.

More people are cycling to work year-round, even in Chicago. The market for durable clothing that moves from the road to the workplace is growing, and Mr. Shaun is looking to fill that niche.

Mr. Shaun, 39, works in small batches and develops three or four new products every few months. His current line offers four types of pants and a shirt jacket made from leftover Burberry trench coat material. He keeps his business local: All garments are manufactured in Chicago.

One of the company’s most popular garments is the Nara Wool Bender Pant, made from an eco-friendly wool and polyester blend fabric from Japan-based Teijin Fibers Ltd. There’s no petroleum used in the textile’s manufacturing and the polyester is recycled from plastic bottles. Teijin worked with Mr. Shaun for two years to get the textile right so it could perform well for the mix of intended functions. The pants don’t need dry cleaning, which is better for the environment, too.

Another part of Mr. Shaun’s sustainable mission is to achieve zero waste. The company’s Afterward Program enables people wearing his clothes to swap them out for something new at discounts if the pants get messed up in a crash or if customers just want to freshen their wardrobe with a new piece.

Locals can buy his clothes at Connect, his Wicker Park storefront (with irregular hours) that also doubles as space for his sideline gig, 3.zero, a digital and branding studio. His clothing also is sold online and in cycle-centric retail stores in San Francisco, Seattle and Portland, Ore.

Mr. Shaun declines to discuss revenue, but says sales in 2011 were off to a strong start. He’s self-financed along with two private business partners. He’s looking for potential investors to develop the business to a bigger wholesale distribution model.

Crain’s met with Mr. Shaun (he goes by Shaun, actually) to learn about the challenges of creating sustainable clothing for a savvy shopper.

Crain’s: Why do you have a limited selection of clothing items?

Mr. Shaun: I’m highly focused on one piece at a time. I don’t have big committees like Nike or Apple. From first sketch to last stitch, the painstaking process takes a long time. I’m not going to put a product out just to fill the store.

Sales reps tell me I need more pieces to round out my collection. They’re probably right, but I design it, resource the textiles, watch over the factory, the finishings, and I test everything with a small quality group of likeminded people who are influencers to help me make the final decisions. These people are very diverse: Some care about the environment, some care only about the design, some only care about how they perform on and off the bike. It took 30 samples and a year and a half to fine-tune the first pant and get it into final production.

Crain’s: What’s so unique about the fabric and design of the pants that sets it apart in the market?

Mr. Shaun: I’m very much into technical fabric. I’m a textile geek.

One of the new textiles is made from Polartec, called NeoShell, and it breathes 100 times better than Goretex. We’re only one of a handful of brands that got access to it, and that’s in the some of the pants I designed. Polartec is made in the U.S., and that’s important to me as well.

Crain’s: Why were you so intent on manufacturing your clothing line locally?

Mr. Shaun: I was bent on making this in Chicago because I want to put my dollars back into my community. I’ve seen the financial crisis here through this macro economic time. I can’t change the world but I can change a small corner of it.

When you talk about the triple bottom line and being a socially responsible business, some people get lost. There’s lots of brand names made in China and all over the world. They can be made of the most sustainable fabrics and textiles and have the most socially responsible factories in China, but what’s more sustainable than making it in your own backyard here in Chicago?

Crain’s: Where do most people shop for your pants and other pieces?

Mr. Shaun: About 70% of sales are happening online, and 20% of our purchasers are wholesale. Another 10% comes from our retail showroom on Milwaukee Avenue. I’m getting pretty aggressive with the wholesale side.

Crain’s: How are you positioning yourselves for growth in the years ahead?

Mr. Shaun: We’re highly focused on figuring out how to still be a core commuter brand and also be able to be in boutiques and select department stores because of the aesthetic. Going into 2012 and beyond, we want to be able to be in the active commuter cycling market, and we want our design and product to translate into the boutique realm seamlessly.

The boutique side doesn’t care about the technical attributes. The cycling side cares about both the technical and the aesthetics. No one has found that sweet spot yet. The biggest challenge I have every day is to be both and not lose our DNA.